These smart valves can autonomously modify their Procedure determined by altering circumstances, resulting in extra effective and optimized industrial procedures. Furthermore, integrating pneumatic valves with World wide web of Matters (IoT) platforms allows remote checking and info analytics, allowing for predictive upkeep and proactive conclusion-building.

A rotary pneumatic actuator can make some thing go inside a round motion. As an example, a rod in a rack and pinion push program is employed to make rotary motion.

Actuation Procedures Pneumatic Command valves could be actuated working with different strategies, such as diaphragm, piston, and rotary actuators. Understanding the discrepancies involving these actuation solutions is vital for selecting the ideal valve for a particular application.

This can be the preferred directional Regulate valve mainly because it can increase and retract double-performing cylinders, providing a wide array of Command abilities. Such a valve includes an inlet port, two outlet ports and two exhaust ports.

Circulation Traits Comprehension the circulation qualities of pneumatic control valves is essential for making sure exact Charge of fluid or fuel flow. Valves may possibly exhibit linear, equal proportion, or speedy opening circulation attributes, Just about every suited for particular Manage programs.

If your cylinder was at mid-stroke in the event the crisis prevent was pressed, when air is reapplied, the valve will command the cylinder to continue motion to the first energized situation, even with both equally solenoids over the valve de-energized. This movement, due to the maintained valve place, could potentially cause troubles.

This kind of compressed air look at this web-site valve refers to the fashion in which the air-flow course is switched. Allow’s take the two-way directional valve as described previously as our example in this article. For every port on the valve for being within an open up or closed posture, an actuator need to go a valve spool to its place.

Pneumatic Command valves can cut down stress in the controlled way through the use of actuators and positioners that are managed by a controller. Controllers can detect strain fluctuations and alter the air provide signal towards the pneumatic positioner.

Modular wiring is typically utilized with manifold mounted valve configurations. This wiring generally consists of a D-sub connector embedded within the manifold base. This provides an efficient and thoroughly clean integration option for large pneumatic units.

Elements which include stream capability, force fall, and inherent stream attributes are affected by the kind of valve trim utilized. Mastering the selection and configuration of valve trim is very important for obtaining precise and economical stream Handle in pneumatic units.

Views and viewpoints expressed by a guest creator are solely their own individual, and do not essentially symbolize All those of ISA. Posts made by visitor authors are actually matter to see evaluation.

An electrically activated solenoid ordinarily shifts the valve spool or poppet to immediate flow. Several programs make use of the valve's uncomplicated on-off functionality to interlock, isolate, and connect numerous program areas.

Generally, you'd shift view these valves by applying Electricity to them along with your hand or toes. A drive-pull movement or simply urgent a button would be essential via the operator.

Moreover, analyzing the Manage sign and actuator reaction might help pinpoint the supply of effectiveness troubles. Consult with reputable resources like Valve Journal or Plant Engineering for thorough information on troubleshooting pneumatic valve challenges.

Mara Wilson Then & Now!

Mara Wilson Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Anthony Michael Hall Then & Now!

Anthony Michael Hall Then & Now! Shannon Elizabeth Then & Now!

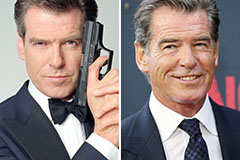

Shannon Elizabeth Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!